OUR SERVICES

EFFLUENT TREATMENT PLANT

Nirmal water Tech Design ,manufacturing, Supply, Erection and commissioning of Effluent Treatment plant. These effluents are harmful to the environment and cause pollution. The plants are developed and engineered to handle these effluents for a quality discharge in order to meet the strict pollution control norms.

We analyze the effluent sample for different effluent parameter as per composition carry out this testing in Govt. authorized lab(NABL Approved) and suggest the treatment scheme. Chemical dosing method to suitable for your application.

Our effluent treatment plant matches the international and national standard norms. Our plant remains odorless, compact & sturdy design and quick to install.

Capacity range:- 1m3 to 1000m3

Technologies in Effluent Treatment Plant:

- Flash Mixer/pH correction/Agitation Tank

- Floculators

- Aerobic Reactor

- UASB

- Primary & Secondary Tube settler

- PAC & POLY Dosing System

- Tertiary Treatment of Filtration

- Chlorination DisInfection System

- Advanced Filtration systems like UF,RO for Zero liquid discharge

- DAF

- OIL SKIMMER

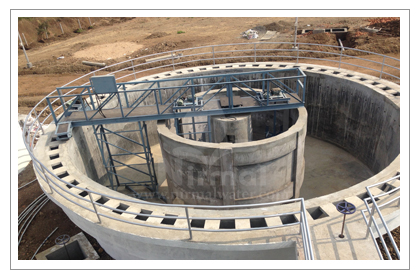

CLARIFIER SYSTEM

Clarifiers are settling tanks built with mechanical means for continuous removal of solids being deposited by sedimentation.[1] A clarifier is generally used to remove solid particulates or suspended solids from liquid for clarification and (or) thickening. Concentrated impurities, discharged from the bottom of the tank are known as sludge, while the particles that float to the surface of the liquid are called scum.

Advantages:

- Slow Moving turbine minimize floc shear

- Fully Automated

- High efficiency turbine for reducing energy

- High quality design offer as per customer need

Dissolved Air Flotation (DAF)

Dissolved air flotation (DAF) is a water treatment process that clarifies wastewaters (or other waters) by the removal of suspended matter such as oil or solids. The removal is achieved by dissolving air in the water or wastewater under pressure and then releasing the air at atmospheric pressure in a flotation tank basin. The released air forms tiny bubbles which adhere to the suspended matter causing the suspended matter to float to the surface of the water where it may then be removed by a skimming device.

The typical industrial wastes treated by flotation are paper mill backwater, oily wastewater as well effluents from sugar, dairy, textile industries and tanneries.

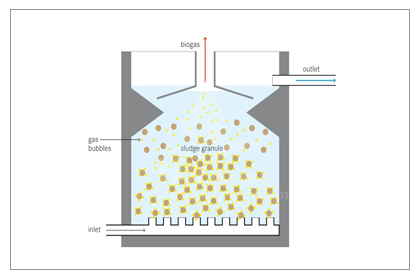

Upflow anaerobic sludge blanket (UASB)

Upflow anaerobic sludge blanket (UASB) technology, normally referred to as UASB reactor, is a form of anaerobic digester that is used for wastewater treatment.

The UASB reactor is a methanogenic (methane-producing) digester that evolved from the anaerobic clarigester. A similar but variant technology to UASB is the expanded granular sludge bed (EGSB) digester.

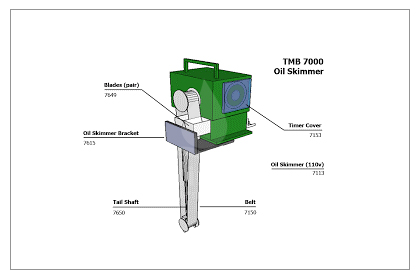

OIL SKIMMER

An oil skimmer is a device that separates oil or particles floating on a liquid surface. A common application is removing oil floating on water. Oil skimmers are not oil-water separator devices. They are used for oil spill remediation, as a part of oily water treatment systems, removing oil from machine tool coolant and removing oil from aqueous parts washers.

Application:

This ETP projects have been covered in various industries like- Textile

- Beverages

- Sugar Mills

- Refineries

- Automobiles

- Pharmaceuticals

- Hotels and Resorts etc

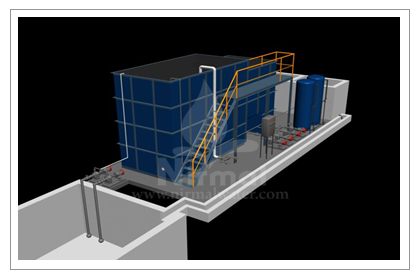

EFFLUENT TRATMENT PLANT (ETP) WITH REACTION TANK

AIR DIFFUSION