OUR SERVICES

SEWAGE TREATMENT PLANT

Sewage treatment is the process of removing contaminants from wastewater, primarily from household sewage. It includes physical, chemical, and biological processes to remove these contaminants and produce environmentally safe treated wastewater (or treated effluent). A by-product of sewage treatment is usually a semi-solid waste or slurry, called sewage sludge, that has to undergo further treatment before being suitable for disposal or land application.

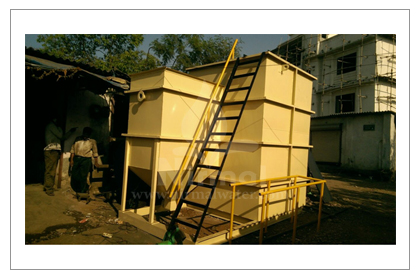

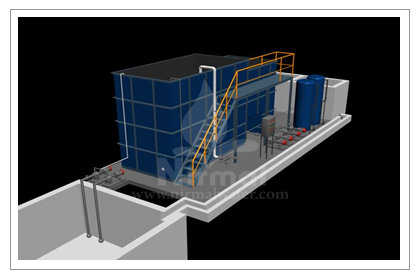

We are prominent manufacturer of Sewage Treatment Plants that are extensively used for treating sewage before dispersing it into rivers and oceans. We offer both customized and standardized sewage treatment plants for Industry, housing societies, commercial complexes, hotels and hospitals.

Capacity Range:-10m3 to 1000m3

TYPE OF SEWAGE TREATMENT PLANT

- PACKAGED TYPE(MS FABRICATED)

- CIVIL

MAIN TECHNOLOGY THEME FOR STP:

MBBR / FAB

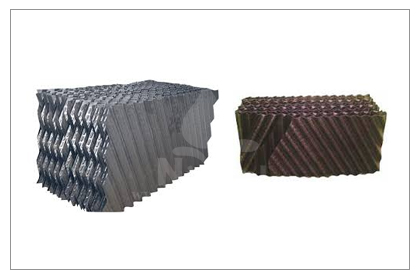

Moving Bed Bio Reactor/Fluidized Bio ReactorThe MBBR system consists of an aeration tank (similar to a activated sludge tank) with special plastic carriers that provide a surface where a biofilm can grow. The carriers are made of a material with a density close to the density of water (1 g/cm3). An example is high-density polyetylen (HDPE) which has a density close to 0.95 g/cm3. The carriers will be mixed in the tank by the aeration system and thus will have good contact between the substrate in the influent wastewater and the biomass on the carriers

The aeration is imparted by Diffused type aerators installed in the tank. The biological treatment method followed is of Moving

Bed Bio Reactor( MBBR), this is also known as Fluidized Bio Reactor ( FAB ). The air is induced in the tank from bottom and it moves upward through moving Media. Moving media due to its movement ensures full utilization of oxygen in the air before it reaches top. The bacteria's which form film on the moving Media utilizes this oxygen and degrades the substrate coming from the sewage water. Increased surface area increases the quantum of the biomass to great extent and thus can sustain shock loads.

The Moving film of bacteria's falls down as soon as its thickness increases beyond certain limit. The anaerobic growth at the bottom most layers makes it loose and it falls down. This makes the maintenance of biomass fully automatic. The sludge settled at bottom is drained out, by Sludge transfer pump into Sludge drying bed.

The overflow of Aeration tank is allowed to pass through a Tube Settler. Any carry over of the suspended solids are settled here. The clarified effluent that overflows from Tube Settler is chlorinated with Sodium hypochlorite solution for disinfection and then filtered is a pressure filter. Alum solution is dosed for coagulation of suspended and colloidal impurities prior to the filtration. The filtered, treated effluent can very well be used for irrigation or discharged into drains as it confirms to the standards stipulated by Pollution

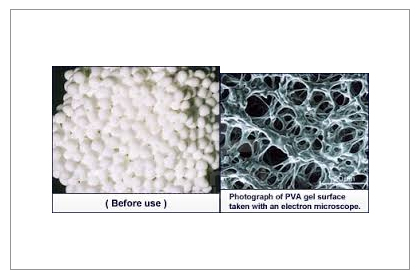

Gel Media Technology

PVA Gel is a biocarrier used to enhance wastewater treatment and thus protect our Earth’s Environment. Through over a decade of research and development, the product PVA Gel beads has established as an effective biological wastewater treatment technology. PVA gel is a Porous Hydrogel that is ideally suited for immobilization of microorganisms essential for the degradation of environmental pollutants.

MBR- Membrane Bio Reactor

Membrane bioreactor (MBR) is the combination of a membrane process like microfiltration or ultrafiltration with a suspended growth bioreactor, and is now widely used for municipal and industrial wastewater treatment.

MBR processes can produce effluent of high quality enough to be discharged to coastal, surface or brackish waterways or to be reclaimed for urban irrigation. Other advantages of MBRs over conventional processes include small footprint, easy retrofit and upgrade of old wastewater treatment plants.

SAFF-Sub Merged Fix Film Aeration Technology

Submerged Aerated Fixed Films (SAFF) technology is a process used to reduce the organic loading of residential and commercial sewage / waste water, and in doing so will reduce the Biological Oxygen Demand (BOD) and a significant quantity of Suspended Solids (SS) which if otherwise untreated would contaminate river and sea outfalls, in other words it is used to substantially improve effluent discharge quality.

As with traditional sewage treatment, Submerged Aerated Fixed Films Technology too uses three stages of dealing with commercial and residential sewage / waste water.

SBR-SEQUENTIAL BATCH REACTOR

Sequencing batch reactors (SBR) or sequential batch reactors are a type of activated sludge process for the treatment of wastewater. SBR reactors treat wastewater such as sewage or output from anaerobic digesters or mechanical biological treatment facilities in batches. Oxygen is bubbled through the mixture of wastewater and activated sludge to reduce the organic matter (measured as biochemical oxygen demand (BOD) and chemical oxygen demand (COD)). The treated effluent may be suitable for discharge to surface waters or possibly for use on land.

Stages in Sewage Treatment Plant:

- Aeration System-Diffusing air by germen make product

- Activated Sludge Process

- MBBR Media

- Membrane Bio Reactor

- Carbon & Sand Filtrations

- Chlorination Dis Infection System

- Low Power Consumption

- Easy Maintenance

- Small Foot print, Compact Plants

- Electrical Panel (Semi automatic/PLC)

- Sludge Drying Bed

- Advanced Filtration systems like UF,RO for Zero liquid discharge.

Application:

This STP projects have been covered in various industries like- Industry

- Hospital

- Residential Township

- Commercial shops

- Universities & large Educational institutions

- Sugar Mill/Karkhana

PACKAGED STP

AIR DIFFUSION